Technologies

FlexAir technology operates using low volume, ultra-high velocity forced air impingement to deliver the energy required to evaporate ink and coating solvents, and to raise the web temperature to cure the ink and coating solids to appropriate levels in your overall converting process.

FlexAir offers a variety of designs to fit almost any drying need including primers, graphics, adhesives, or varnishes applied with any evaporative ink industrial printing process. We combine our technology with years of experience creating the most efficient and effective drying system solutions.

A-Class

Key Advantages

- Highest Energy Efficiency

- Pre-heated Nozzles

- Widest Web Capability

- Enhanced Turbulent Pocket

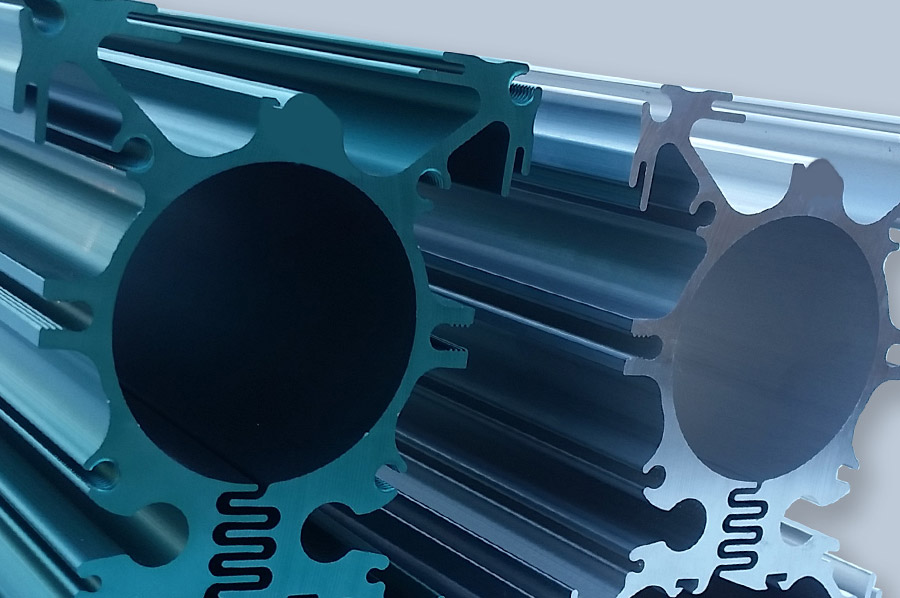

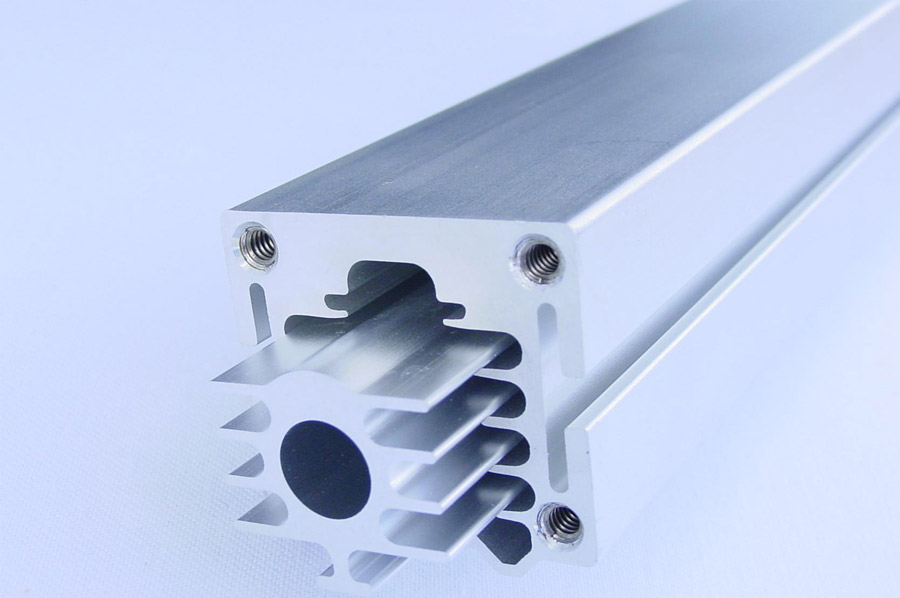

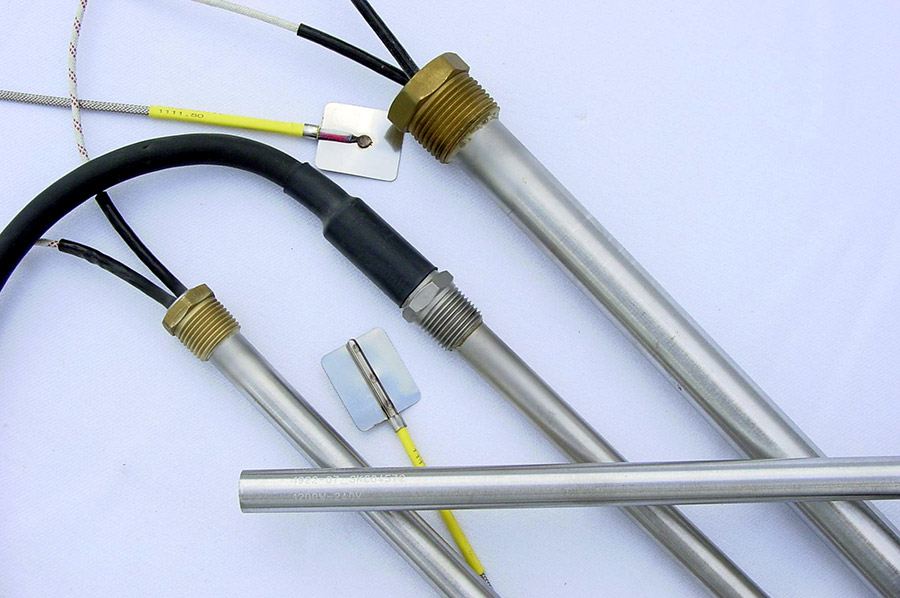

FlexAir’s newest hybrid technology, A-Class features proprietary aluminum extrusions with integrated long-life electric cartridge heaters. Driven by High Pressure Turbo Blower technology, A-Class systems offer the industry a revolutionary high performance forced air drying solution.

Learn About A-Class TechnologiesB-Class

Key Advantages

- High Pressure Blower Based Systems

- Heated Air Supply

- Unlimited Dryer Shapes

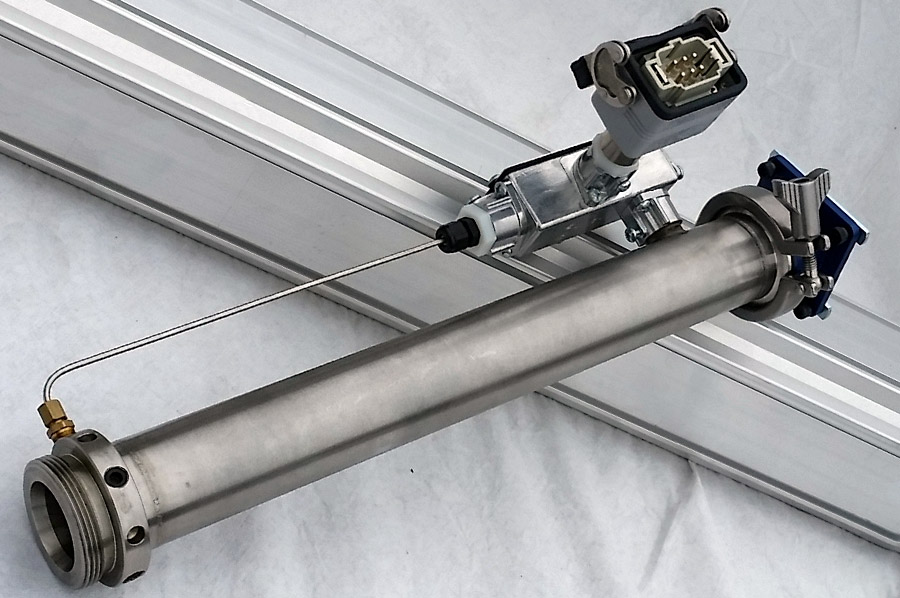

FlexAir’s second generation B-Class blower-based technology takes low pressure air to its highest level of drying performance. The supply air temperature is raised with an open-coil heater before being delivered to a tubular or custom welded plenum. By separating the heater from the dryer, the dryer can be fabricated to adapt to virtually any exotic drying requirement.

Learn About B-Class TechnologiesC-Class

Key Advantages

- Compressor Based Systems

- Highest Drying Effectiveness

- Pre-Heated Air Bars

- Most Compact and Portable Technology

- Temperature and Pressure Control

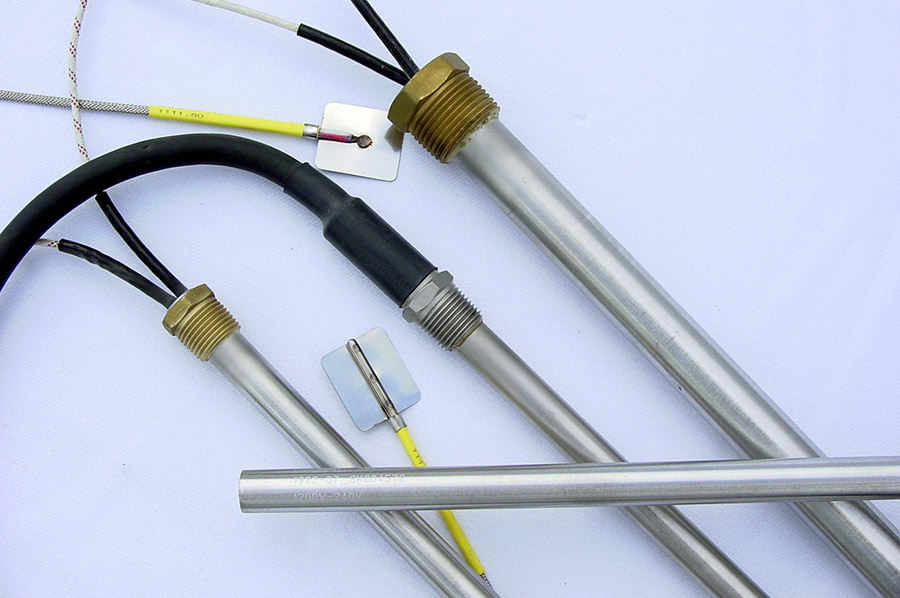

FlexAir’s introductory technology, C-Class features proprietary aluminum extrusions with integrated long-life electric cartridge heaters. Driven by compressed air, C-Class dryers offer the most compact and highest performance dryers with the largest choice of designs developed through 15 years of application. Highly adaptable, open and reconfigurable systems provide low risk for future drying needs.

Learn About C-Class Technologies